History

OCTOBER 12, 1960 |

The Velikiye Luki Reostat plant was organized to produce low-voltage start-up and control equipment in accordance with the Resolution of the Leningrad Economic Council No. 40 in connection with the sharp increase in the needs of the national economy for this equipment on the basis of an existing textile factory. The number of employees of the factory was 123 people, and all of them were enrolled in the staff of the plant together with the management staff. |

|

|

|

March 1961 |

Together with the specialists of the Electrosila plant, the first batch of products was produced, complete with parts supplied by the Electrosila plant. It was necessary to master the production of parts of its own production. Therefore, first a mechanical stamping site is created, then a product assembly site.

In the same year, an electroplating section, a painting conveyor and a pressing section of parts are put into operation.

|

|

|

|

JANUARY 1963 |

In connection with the creation of the Leningrad Electric Machine Building Association, the Reostat plant became part of it. |

|

|

|

1964 - 1965 |

The director of the plant continued to expand its production. A new two-storey production building with an area of 1,660 sq. m is being built and put into operation. m along Murmansk Street. |

|

|

|

|

1961 - 1965 |

A lot of work has been done at the Reostat plant in the field of mechanization and automation of production, improvement, modernization and quality of low-voltage equipment. |

|

|

|

1968 |

The management of the Reostat plant continues the reconstruction of its areas. The construction of a second similar two–storey building is coming to an end, and the production of automatic pair fuses-6.3 A. In the same year, the development of push-button switches of the KE series is underway. |

|

|

|

1970 |

The full development of the production capacities of the two-storey building is coming to an end, where the assembly of cultural and household goods, fuses of PAIRS-6.3 A, and a contact welding section are located on the 2nd floor. |

|

|

|

1973 |

A new production building is being introduced, where the blanking and stamping section is located. |

|

|

|

1971 - 1975 |

More than 130 units of high-performance equipment have been purchased and put into production. |

|

|

|

1985 |

The plant became a participant in a large-scale economic experiment, which set the task of improving the work of the industry of the USSR. |

|

|

|

1985 - 1991 |

The plant has mastered the production of electrical sockets, ARV-SDP regulators, mechanical brushes, and a PAG automotive device. |

|

|

|

1992 |

Political events in the country of the USSR, terrible inflation led to a catastrophic drop in production volumes. |

|

|

|

1995 - 1996 |

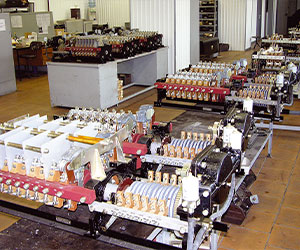

Tape blocks of resistors were mastered, which were widely used and are used in the design of the electric drive of the engines of subway cars, electric trains, trams. |

|

|

|

1997 - 1998 |

We mastered a complete set of equipment for driving the engine of subway cars. |

|

|

|

1999 |

We mastered the production of fuses PAR-25 A and became the only manufacturer in Russia of automatic fuses for currents from 4 A to 25 A (4 A, 6.3 A, 10 A, 16 A, 25 A). |

|

|

|

1999 - 2000 |

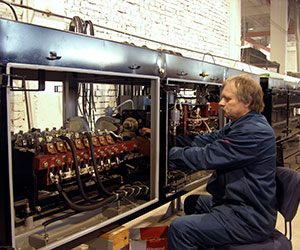

We have mastered the production of overhaul of equipment, the electric drive of the engine of subway cars. |

|

|

|

2001 |

The development of the production of equipment for the electric drive of the engine for electric train cars began. |

|

|

|

2003 |

The plant has certified the products in accordance with the international standard ISO 9001-2000. |

2001 |

The company supplies electrical equipment for ED9 electric trains manufactured by the Demikhov Machine-Building Plant. |

|

|

|

2007 |

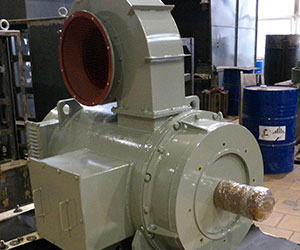

The production of the TED-3 traction motor for electric trains has been mastered. |

|

|

|

2009 |

The plant launched the production of large electric machines for excavators EKG-10, EKG-12, EKG-15, ESH40.100, ESH20.90, ESH11.75, general industrial engines and engines for drilling rigs, low-voltage devices designed to control the main drives excavators. |

|

|

|

2011 - 2013 |

Mastering the production of sets of electrical equipment for BelAZ dump trucks with a lifting capacity of 136 and 240 tons. |

|

|

|

2021 |

Reostat's product line includes sets of equipment for mining excavators EKG-18 and EKG-15. |